Qiulin

|

- Professional Title:Professor

Supervisor of Doctorate Candidates

Alma Mater:Graguate School of Chinese Academy of Sciences

Discipline:Thermal Engineering

School/Department:School of Energy and Environmental Engineering

Business Address:Office 1107, Jidian Building, University of Science and Technology Beijing

Contact Information

Contact Information

- ZipCode:

- PostalAddress:

- Email:

- Research Focus

High throughput design, calculation and preparation of Low-dimensional carbon materials

China's Chip process is still in the transition stage from 14 nm to 7 nm, two generations behind developed countries, and the shortage of advanced Chip needs to be solved urgently.In the research and development of high-performance Chip, the efficient diffusion of Joule heat becomes a key problem with the decrease of size, the increase of density and the increase of operating frequency of FET. In order to solve the Chip heat dissipation bottleneck, the research focuses on the micro-nano scale interface heat transfer mechanism and regulation, the development of high-thermal nanoscale carbon nanoscale materials (such as graphene, carbon nanotube fibers, hybrid carbon nanotube arrays, etc.), and the integration with Chip packaging structure combined with high-performance computing, machine learning, automation platform and other methods to achieve rapid parallel preparation of materials. Key performance data are obtained by efficient characterization techniques such as X-ray diffraction, Raman spectroscopy, etc. Thus, the traditional development cycle is greatly shortened, the design and application of high-performance materials are promoted, and the heat dissipation problem is overcome to help independent research and development breakthrough.

(1) Design calculation: Structures are generated in batches using massive data from databases such as The Materials Project, AFLOW, and NOMAD. After feature engineering processing, machine learning is utilized for analysis to mine parameter combinations and screen potential structures with excellent performance. The structure, properties and stability of materials can be predicted rapidly by combining theoretical models such as Density Functional Theory (DFT) and molecular dynamics simulation (LAMMPS) with machine learning. The performance of the generated structure is evaluated by calculating parameters such as phonon state density, interaction energy, phonon overlap energy, dispersion relationship, phonon mode participation rate, phonon wave packet, atomic temperature distribution, and phonon lifetime. The use of simulation calculation and database mining can quickly screen materials with potentially excellent performance.

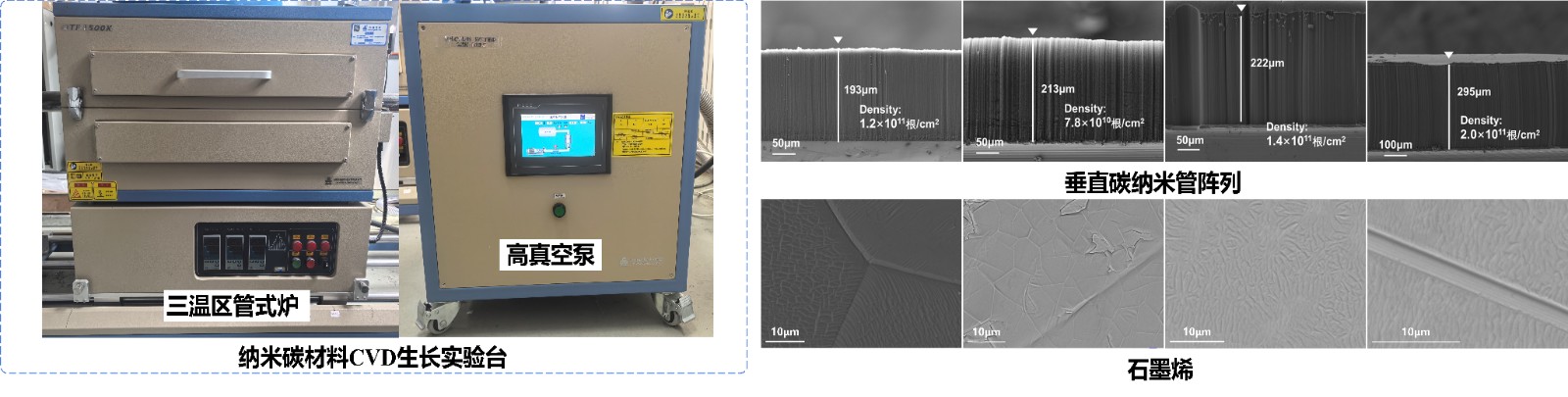

(2) Intelligent high-flux nanoscale carbon material preparation system: Based on the accumulated foundation in nano-carbon material preparation, Our team endows the equipment with the ability to independently adjust preparation parameters, thereby achieving the collaborative balance and optimization of multiple performance parameters of the material, and efficiently promoting the research and development process within a multi-dimensional parameter space. The thermal conductivity of carbon nanotube fibers was enhanced through a hierarchical regulation strategy. By using polar molecules to shorten the carbon tube spacing, activating phonon resonance with precious metal particles, and optimizing the content of polymer molecular chains, the thermal conductivity was increased to 374 W/m K (comparable to the international advanced level of 380 W/m K). In terms of carbon nanotube arrays, a strategy of phased regulation of the microstructure contact area was adopted. The preparation process was optimized to enhance the uniformity of the array, and the contact area with the heat sink was increased through coating and mechanical shear compression. The interfacial thermal conductivity reached 3.3×10⁶ W/m²·K (internationally leading). Based on the technological accumulation in the preparation of nano-carbon materials, an intelligent mechanical hand - high-throughput preparation integrated platform has been constructed. Through the deep integration of multi-axis collaborative robots and autonomous parameter control algorithms, the entire process from raw material input to finished product sorting is achieved with unmanned operation. Multiple groups of preparation experiments were completed simultaneously in a single batch, and the preparation efficiency was increased by more than 100% compared with the traditional mode.

Video: Sample grasping by a multi-axis intelligent mechanical hand

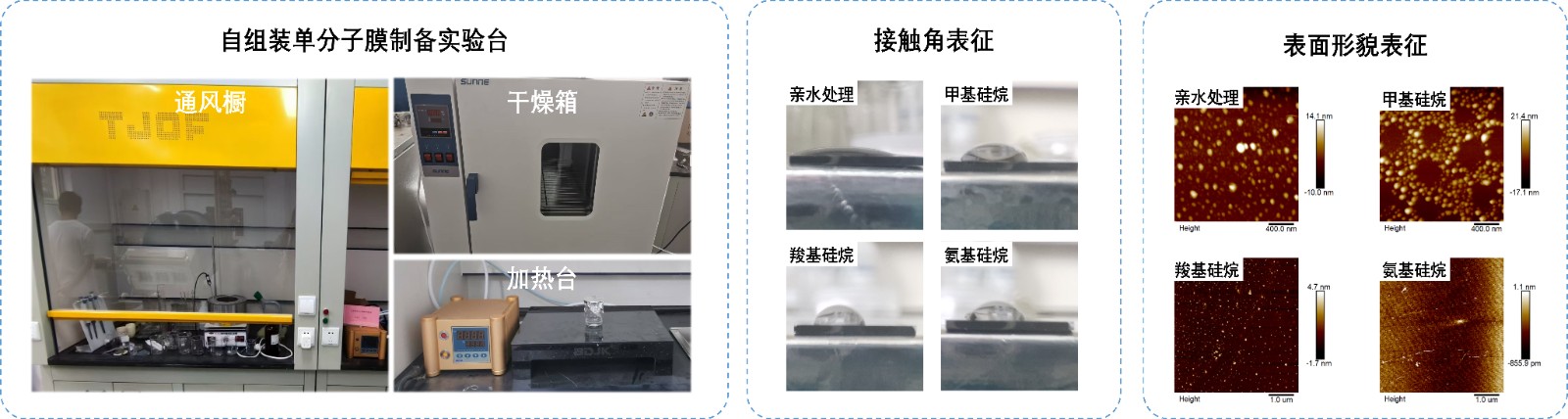

(3) A preparation system based on self-assembling monolayer composites: Based on the previous research on the interface control of Self-Assembled Monolayers (SAMs), our team has developed a tunable composite preparation method aimed at achieving the balance and optimization between the thermal conductivity and mechanical properties of the material. By regulating the grafting density of SAMs, optimizing the dispersion process of fillers and precisely controlling the composite ratio, the thermal resistance of the filler/epoxy interface was significantly reduced. In order to deeply explore the grafting of SAMs on the surface of silicon substrates, in this study, the morphological characteristics and roughness of the composite material surface were observed by atomic force microscopy, thereby revealing the influence mechanism of the interface structure on the thermal conductivity.